Japan’s Energy Saving is not like “wringing out a dry washcloth”

- Putting an end to the lost 20 years -

First Published:Kankyo Business Online (11 May 2015)

in Japanese

My previous column examined the “Energy Mix (Electricity Mix)” proposal by the Ministry of Economy, Trade, and Industry (METI), including its significant passivity towards the introduction of renewable energy and the great emphasis on coal fired power generation which is unusual internationally. Alongside this, another major issue is the passivity also towards energy saving.

In the materials submitted by METI to the 8th meeting of the Subcommittee of Long-term Energy Supply-Demand Outlook, METI predicts that by year 2030, the electricity demand will not be reduced from 2013 levels, but will actually increase by 1.4%. A further problem is the distortion seen when looking at the breakdown, with an approximately 20% reduction goal for the residential sector, whereas an increase of 22% is anticipated for the industrial sector.

Weak Goals for the Industrial Sector also in CO2 Emission Reductions

At around the same time as the Electricity Mix proposal was published, Japan also produced its greenhouse gas emission reduction goals for the year 2030. The goals state that in comparison to 1990 emissions, Japan will strive for an 18% reduction – falling far short of the EU’s 40% emission reduction rates. The lack in consistency with the Japanese government’s own international pledge of an 80% reduction by 2050 has already been criticized by various parties, and so it will not be repeated here.

It is hereby important to note that these emission reduction goals, like the Energy Mix proposal, are too easy on the industrial sector. According to Japan’s draft pledge for greenhouse gas emissions reductions, targets for energy-origin CO2 reductions by 2030 are cutbacks of 40% for the business sector, 39% for residential, 28% for transportation, and yet only a 6.5% reduction for the industrial sector.

Provisionally, if emission reduction goals for the industrial sector were set at around 40%, as for the business and residential sectors, the total combined sector reduction goals (in comparison to 2013) could produce a 12 percentage point improvement, from today’s 25% to 37%.

The Myth of the “Dry Washcloth”

The setting of such weak reduction goals for the industrial sector is based on the “myth of the dry washcloth” – a Japanese saying which implies a situation which has dried up, with no potential for future development or improvement. This refers to the Japanese government’s position that the country’s industrial sector has already exhausted its efforts in energy saving, with nothing more to be done.

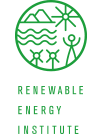

It is clear by looking even only at the data made public by METI that this myth is completely inaccurate. Figure 1 shows the trends in energy efficiency in Japan’s manufacturing industry, from the 2014 Energy White Paper. The data shows that certain improvements did continue from the end of the 1973 Oil Crisis through the mid 1980s, yet in the just over 20 years since then, the situation has stagnated.

10% Loss in Manufacturing Industry Energy Consumption through Degradation of Thermal Insulation Material

Proponents of the aforementioned myth may use such data to defend their position, as proof that Japan has indeed already exhausted its energy saving potential. Here, it is important to note the materials submitted by The Energy Conservation Center, Japan (ECCJ) to the Energy Saving Subcommittee established by METI. These materials point out the cross-sector problem of expansion of energy loss as a result of aging facilities and lack of proper maintenance, as follows:

- Facilities introduced around the Bubble period of the 1970s-1980s have across the board surpassed their service lives, and deterioration is advancing.

- Reductions in repair costs due to worsened management environment and retirement of veteran personnel have led to lack of proper maintenance, and furthermore, to deterioration of equipment functions, which are likely causing expansion of energy loss.

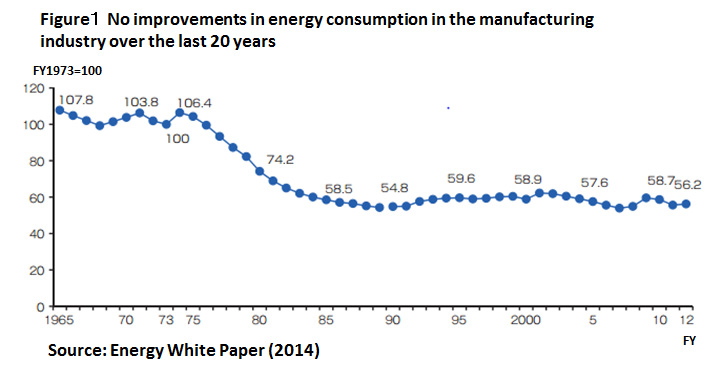

The materials present boilers as a concrete example, namely, insulation performance degradation of heat supply facilities. Here, the aging of outdoor piping and lack of proper maintenance leads to degradation of insulation materials, as in the photograph below. The data indicates the eye-opening fact that the loss of heat resulting from this alone “is a great loss of more than 10% energy consumption within Japan’s manufacturing industry.” (See Figure 2 and accompanying photograph).

A loss of 10% of energy consumption within the manufacturing industry due to degradation of insulation materials shows that taking countermeasures against this point alone would make possible energy savings of 10%. And, this is but one small example.

This shows clearly that the industrial and manufacturing sectors are not at all in the situation of the mythical “dry washcloth.”

Komatsu Ltd.’s Halving Electricity Usage Project

Some ambitious corporations are voluntarily engaging in initiatives for significant reductions in energy consumption. A representative example of this is Komatsu Ltd.’s “Halving Electricity Usage Project.” This has been widely introduced already and so this column will not go into detail, but the point drawing attention is that efforts for energy efficiency are going as far as to even revisit the production process itself. Komatsu states that “we can reduce power used during processing and idling with inverter control and fine-tuned stopping in auxiliary machinery such as pumps and motors. We can also shorten both processing and idling times by improving processing speed and capacity utilization, machining time.” A further characteristic point is that while the industrial sector traditionally overlooks utility factors including lighting and air conditioning, Komatsu is making efforts towards electricity reductions in these areas also.

Policies to Realize the Potential Energy Savings are Needed

There is great potential for energy savings in not only the business and residential sectors of Japan, but also in the industrial sector; and indeed there are already corporations that are voluntarily and actively implementing initiatives for this purpose. However, in order to fully unlock the great energy saving potential, make energy consumption itself throughout Japan more efficient, and realize a significant reduction in greenhouse gas emissions, voluntary efforts alone are insufficient.

The Japanese government’s policies for energy saving until now have been consistently limited to promoting voluntary measures. Within current discussions at the Energy Saving Subcommittee, the insufficiency of existing measures is being somewhat recognized within the “Mid-term examination of discussions to date. ” Yet the stance in regards to regulations and the role of the national government is problematic: “Indication of governmental guidelines for business operators could be effective. However, regulations that would limit the actions of business operators to the extent of being economically or technologically difficult to achieve would obstruct business growth.” Thus, the extent of measures introduced by the government remains limited.

One of the policies the government is neglecting to the point of not even considering is a cap and trade system, putting in place mandatory total reductions and a system for trading emissions. The introduction of such a system in Japan is limited to the Tokyo metropolitan area, and while the national government passes over it, its introduction has even expanded to South Korea and China. If the introduction of such measures to strongly promote energy efficiency are put off, the “lost 20 years of energy savings” will be prolonged further, and Japan will become far from “the world’s leader in energy savings, ” but instead, as is already happening with the introduction of renewable energy, a country falling backwards in the field of energy savings. This situation must be avoided by any means.